Brief introduction regarding robotics. Robots or we can also be called electro-mechanical device which follows a set of instructions (programmed) to carry for a certain job. The first thing we came to our mind(most people) when we think about robotics is automation. It is also known to perform tasks without human intervention, except for its initial program and instruction being set to a certain robots.

There are many kinds of robotics in industry that can help with their business (robots.net has a wide knowledge in terms of technology included the robotics automation). Machine is the basic example of robotics. It can perform a single task repeatedly with accuracy on a specific operation. It was a program to do a specific task with guidelines and instructions.

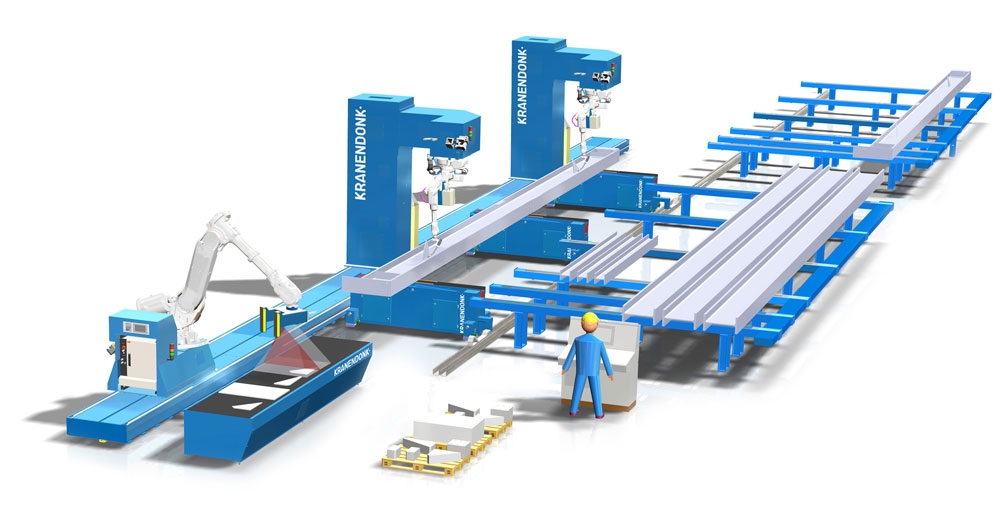

There is also an advanced robotics version than can perform operations adaptively that can change dimension and other settings that using Automating assembly lines as its requirement. Robotics is a machine capable of performing tasks as delicately and accurate as human can do(faster than humans in terms of performing and finishing tasks).

Assembly Robotics

Assembly line robotics can occupy a specific spot between humans and Hard automation. Robotics can move faster and has greater precision and accuracy than humans. It can easily be configured as many times as you want. Assembly line robotics is a low-risk management that satisfies the demand for manufacturing both quality and finance.

Assembly Robots/machine can also be specified with the vision system and force sensing(which is pre-programmed). Vision can help robots/machine to pick up/guide the component from conveyor and eliminating the need of its precise location and can do visual serving that let the robot rotate or translate one piece to make it fit with other functions.

Benefits of automated production lines

Automated production lines is a series of workstations linked by a transfer and electrical system. Each system has a specific task of operations and it is process step by step as it moves along in the pre-defined lines of production sequence. If you have a fully automated production line, you didn’t need any people directly involved in its operations and all part of the process of productions compared to mechanical or just an automated system.

For automated production lines, you can save a man’s power and operation cost, can process fast, reliable and have a precision and accuracy of quality of work. Time saving and effort can also be a benefit if you have and fully automated production lines. In an automated environment, the task involving humans may change to the system design, adjustment monitoring and supervision of the operation rather than controlling the flow of it.

Three Types of Automation

- Hard Automation

- Flexible Automation

- Soft Automation

Hard Automation – is a machine that is designed to perform a specific and highly repetitive task of work. This tas usually has a simple operation because it only designed as a straight-forward and customized operation. Hard automation usually has the lowest first-cost options.

Advantage of Hard Automation

- Low cost-uni

- High Production rate(repetitive task)

- Automated materials handling

- Perform High-Speed task and can outperform human

Disadvantage of Hard Automation

- High-cost initial investment

- Inflexible in accommodating changes

- Modifying can be costly and time-consuming

Flexible Automation – is a machine or equipment that is designed to easily change the sequence of production line for a variety of product mixes. It includes a robotic arm capable of four to six-axis movement with interchangeable heads that can perform a variety of tasks. It has a series of sensors and program logic control of its actions.

The flexibility of the machine can perform possible movement has sensor available and can reprogram the equipment function quickly. Flexible automation is well suited to high mix products that are continually developing for changing its platform. This flexible automation can handle both high and low volume of production with easy and accurately.

This automation is very helpful and highly recommended for large enterprise and medium business enterprise. It can even help the enterprise perform task that is fast, reliable, even can reduce manpower and time performing task.

Advantage of Flexible Automation

- Flexible design and has many varieties

- Recommended for batch production

Disadvantage of Flexible Automation

- High/costly investment

- Lower production rate in terms of hard automation

Soft Automation – is a programmable and more developed than hard automation. It can accommodate a variety of product configurations. The operations containing the soft automation is it was operated and controlled by computer, which was reprogrammed to adjust or make any changes when it comes to operations for different products.

Changing setup for the equipment of a product changeover may be simple as running a different input program or may include some mechanical adjustment to the equipment. Added some flexibility causes the first cost of equipment to be much higher than the hard automation and it is specifically operating at a slower speed than hard automation.

Advantage of Soft Automation

- Variable mixtures of product

- Can deal with product design variation

Disadvantage of Soft Automation

- High unit cost relative to hard automation

- Medium production rate

Automated production lines is a process of raw materials that enter and process it to finish product which leave with little or no human intervention. Accurately and much faster than human production. Automated production lines are fast, reliable and have an accurate production flow than can contribute to the enterprise for reducing production time and cost of manufactured products.

The benefits or use of automated production/assembly lines can significantly reduce the production cost as well as labor cost, minimizing human error, increase its accuracy and ensuring the output of consistency and quality of the product.

The automated productions using machine/robotics free up people for the drudgery of repetitive tasks, although it replaces human labor to replace for automated productions/machine, for labor task that is done in dangerous environments, it can minimize the accident provided with the task production. It can even perform a task that the human can’t be compared to robotics/machine with its size, speed, and endurance.

Robot-Human Collaboration

Collaborative of robot is now eyeing by the big enterpriser, Decreasing its cost, the lighter and more collaborative like a plug and play component generations of robotics with advanced vision and sensor technology that allows even small or medium business to collaborate with human workforces with the assistance of robotics setup.

Having greater accuracy and doing fast and reliable work can increase the production of products and can trend to decreasing cost of initial outlay are attracting the business owner to shift with automated assembly/productions. If the automated assembly provides more products than having none automated, surely the business owner will shift towards as if more production can be produced, it means more income they can get.

Takeaway

After looking back or having said all of the benefits produced above, businesses still consider or study if they will adapt to having such an automated assembly. Not all business needs to be automated. This automated production can be much benefited by the larger enterprises as they need fast and accurate productions. Dealing with the solution is costly but the question of it is it worth it? maybe yes or maybe no, but most of the businesses (small, medium or large)can be affected with these innovations.

This innovation is not just simple, it is revolutionary as it helps many business in many ways, Demand of product is increasing but we can’t afford to lessen the quality of the products. Automated production was the solution for mass production of products which produce more products that humans can be capable of with fast, reliable and maintaining or improving its quality.

Add Comment